grade:

EAA 4403manufacturer:

SK chemmelt index(g/10min):

8density(g/cm³):

0.94Shore Hardness:

25VA/AA Content(%):

18Attribute:

/application:

Sheet /Film /Coatings /Cable ties /Adhesion Promoter/Coating applicationsProduct Name

Ethylene Acrylic Acid Copolymers 4403

Description

Ethylene and acrylic acid (EAA) copolymer resins offer excellent adhesion to polar substrates without the need for primers. Applications include liquid aseptic, dry-food and laminated tube container packaging, and cable shielding.

It has the following benefits:

APPLICATIONS

| Laminates | Film | Foil coatings |

| Cable ties | Coating applications | Adhesion Promoter |

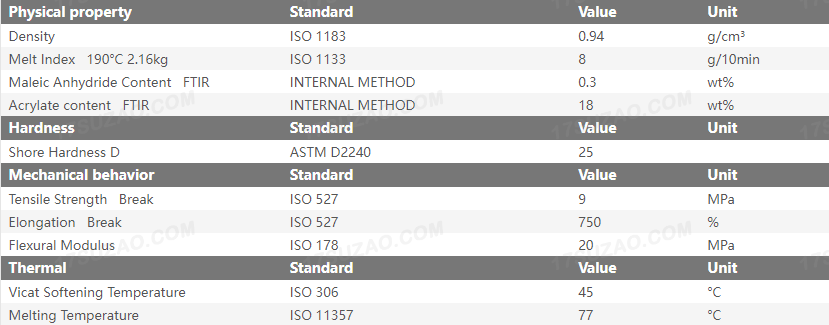

Product Specification

Package and Storage

Selling Units: Single Item

Single Pacage Size: 70*50*15 CM

Single Gross Weight: 25 KG

Logistics Information

Logistics Information

Pricing Information

Pricing Information

Reports Available

Reports Available

If you can not find your target material through the website, please contact us, cause there are so many materials in our company and we did not post them all.

Related Tags :